-

Posts

118 -

Joined

-

Last visited

-

Days Won

1

paolo last won the day on June 20 2022

paolo had the most liked content!

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

paolo's Achievements

-

- 1 comment

-

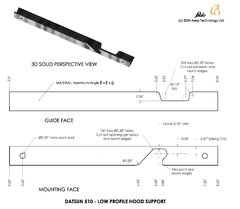

- datsun 510

- low profile hood support

-

(and 1 more)

Tagged with:

-

- 1 comment

-

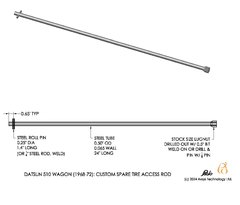

- datsun 510

- low profile hood support

-

(and 1 more)

Tagged with:

-

- 1 comment

-

- datsun 510

- low profile hood support

-

(and 1 more)

Tagged with:

-

Prop rod may require slight bend outward (passenger side) to adjust tension against slide. Round end of rod (grind or file) where it touches guide to ensure smooth operation. Cut stock guide off using spot weld cutter. Remaining hubs seen protruding from brace in image. Smooth nubs and fill as preferred.

- 1 comment

-

- datsun 510

- low profile hood support

-

(and 1 more)

Tagged with:

-

- 1 comment

-

- datsun 510

- low profile hood support

-

(and 1 more)

Tagged with:

-

paolo started following Battery Tray Relocate Front View w Battery , Low Profile Hood Support Install Data , Low Profile Hood Support Brace Prep and 7 others

-

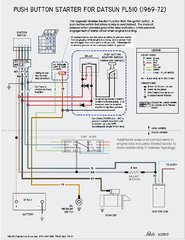

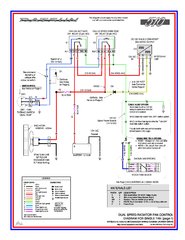

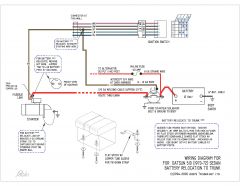

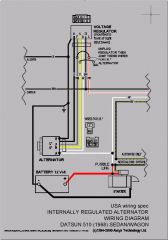

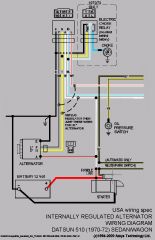

Various modifications or upgrades to the Datsun 510 Wagon (1968-1972 vintage). Some of these mods also apply to the Sedans.

-

-

-

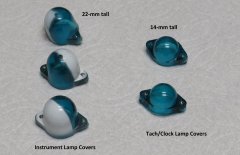

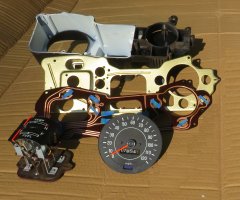

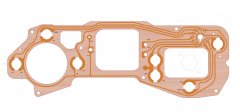

Images of various parts or states of my instrument cluster (dash pod) rebuilds and rebuilding processes.

-

-

-

Glove box lamp parts. 1 - Outer frame (flat piece) from a a cut-out bit of 1/10" plastic of an old computer or electronic widget. 2- Pipe is cut from 3/4" CPVC pipe. 3 - Switch is a normally closed (NC) push-button available for cheap on-line by the 10-pack. 4 - Wires are color matched parts from an old harness with coordinated barrel connectors from VintageConnections.com 5 - LED another online Amazon part. 6 - Socket is typical lamp socket from Datsun 510 instrument cluster panel which fits snugly into pipe. All assembled with hot glue. Paint as desired. Contact me for part sources.

- 1 comment

-

- glovebox lamp

- glove box

-

(and 2 more)

Tagged with:

-

-

paolo changed their profile photo

-