-

Posts

118 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Gallery

Everything posted by paolo

-

- 1 comment

-

- datsun 510

- low profile hood support

-

(and 1 more)

Tagged with:

-

- 1 comment

-

- datsun 510

- low profile hood support

-

(and 1 more)

Tagged with:

-

- 1 comment

-

- datsun 510

- low profile hood support

-

(and 1 more)

Tagged with:

-

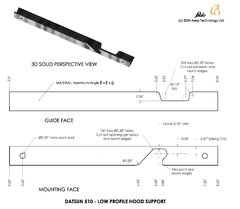

Prop rod may require slight bend outward (passenger side) to adjust tension against slide. Round end of rod (grind or file) where it touches guide to ensure smooth operation. Cut stock guide off using spot weld cutter. Remaining hubs seen protruding from brace in image. Smooth nubs and fill as preferred.

- 1 comment

-

- datsun 510

- low profile hood support

-

(and 1 more)

Tagged with:

-

- 1 comment

-

- datsun 510

- low profile hood support

-

(and 1 more)

Tagged with:

-

From the album: Wagon Mods

Installation Data. Placement shown sets hood raised angle at about 46.5 degrees from horizontal, slightly more than stock. Adjust placement laterally to accommodate preferred hood angle. Install aluminum angle prop rod guide per dimensions in image.© Paolo Musante 2024

- 1 comment

-

- datsun 510

- low profile hood support

-

(and 1 more)

Tagged with:

-

Various modifications or upgrades to the Datsun 510 Wagon (1968-1972 vintage). Some of these mods also apply to the Sedans.

-

- 1 comment

-

- datsun 510

- low profile hood support

-

(and 1 more)

Tagged with:

-

From the album: Wagon Mods

Low profile Support Installed. Prop rod works identical to stock prop rod except need to pull leftward to release rather than forward. Note raised aluminum front strut tower brace near photo bottom. See Front Strut-Tower Cross-brace© Paolo Musante 2024

- 1 comment

-

- datsun 510

- low profile hood support

-

(and 1 more)

Tagged with:

-

From the album: Wagon Mods

Construction Details. Aluminum angle (cut from Home Depot metals part: 3/4" x 3/4" x 1/16" - 3-ft length). Can be constructed accurately enough using a hack saw, drill with bits, and a metal file.© Paolo Musante 2024

- 1 comment

-

- datsun 510

- low profile hood support

-

(and 1 more)

Tagged with:

-

- 1 comment

-

- datsun 510

- low profile hood support

-

(and 1 more)

Tagged with:

-

-

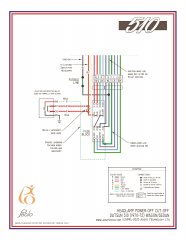

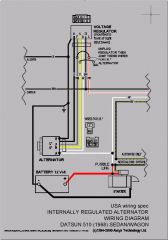

From the album: Useful Data

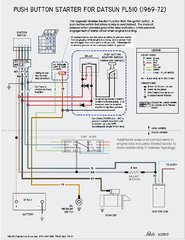

Wiring diagram for a push-button starter system. All needed data and specific notes provided on image. Installation is partially shown in certain images in my Wiring Bits and Odd Ends album.© Paolo Musante 2012

-

- wiring diagram

- datsun 510

-

(and 1 more)

Tagged with:

-

From the album: Wagon Mods

Simple cost effective, very lightweight tower brace made from 1" dia Aluminum tube. Tools needed: Tubing bender (recommended but not required), heavy bench vice, and drill with 3/8" bit. Grinder to smooth edges.© Paolo Musante 2010

-

- datsun 510

- strut tower brace

-

(and 1 more)

Tagged with:

-

From the album: Wagon Mods

Construction Data for alternate battery tray in engine bay, similar to 240Z placement. This tray is designed for a TYPE 51R battery. Tray shown (black) was conveniently made from old computer case. Tray thickness estimated at 14-ga. In service for > 3 years. Aluminum bracketry made from stock purchased from Home Depot (Home/Hardware/Metal Stock/Flat Bars). Bolts all metric sizes (6-mm to tray and 10-mm through frame), length as needed.© Paolo Musante 2024

-

- datsun 510

- battery relocate

-

(and 1 more)

Tagged with:

-

From the album: Wagon Mods

Top view of alternate battery tray in engine bay, similar to 240Z placement© Paolo Musante 2024

-

- datsun 510

- battery relocate

-

(and 1 more)

Tagged with:

-

From the album: Wagon Mods

Front View for alternate battery tray in engine bay, similar to 240Z placement© Paolo Musante 2024

-

- datsun 510

- battery relocate

-

(and 1 more)

Tagged with:

-

From the album: Wagon Mods

Front View alternate battery tray in engine bay, similar to 240Z placement, showing TYPE 51R battery installed.© Paolo Musante 2024

-

- datsun 510

- battery relocate

-

(and 1 more)

Tagged with:

-

datsun 510 Datsun 510 Wagon: Lightweight Spare Tire Access Rod

paolo posted a gallery image in Members Albums

From the album: Wagon Mods

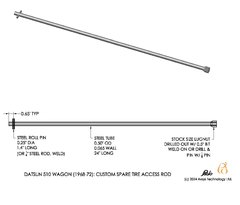

Lightweight alternative to the stock spare tire access/lowering rod & handle. Two approaches with item weights shown. 1. The 24" long rod is custom made from steel tubing. Construction shown an following image. 2. The 28.5" ling rod is the stock rod with a lug nut hammered onto the end. Best & strongest fit is to use square file to expand hole slightly. Welding optional but stronger. Both option eliminate need for the stock rod driver.© Paolo Musante 2025

-

datsun 510 Datsun 510 Wagon: Spare Tire Access Rod Construction Data

paolo posted a gallery image in Members Albums

From the album: Wagon Mods

Construction details for alternative lightweight Datsun 510 wagon spare tire access/lowering tool.© Paolo Musante 2024

-

From the album: nuovo cinquecentodieci

Custom WA state license plate for my nearly perfect, basically stock 1972 4dr Dime. First acquired on 2013.© Paolo Musante 2013

-

From the album: nuovo cinquecentodieci

IDX = I + DX (roman number for 510) -

-

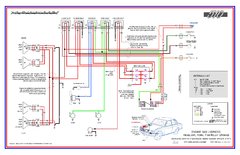

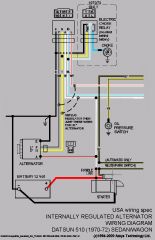

From the album: Useful Data

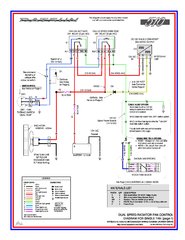

Wiring Diagram for Datsun 510 (68-72) cooling system using electric fan upgrade for two speed fan control - PAGE-1. See PAGE-2 for component notes and design parameters. Component design descriptions for proven as-built system with usage details. Design for stock L16, L18, or L20B engines, Likely a great upgrade for other engine swaps such as SR20, KA24, etc. The devil is in the design details. The circuit set up for a single fan but can be easily adapted for dual fan system. The dual speed system works best using a low temperature dual range switch as described in notes on PAGE-2. Refer to PAGE-2 for important notes about cooling system build.© Axsys Technology Ltd.

-

- datsun 510 wiring

- two speed fan control

- (and 3 more)

-

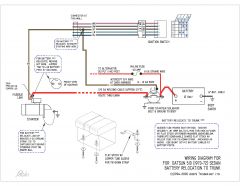

From the album: Useful Data

Wiring Diagram for Datsun 510 (68-72) cooling system using electric fan upgrade for two speed fan control - PAGE-2. The goals of the lower voltage, two speed fan control design is to reduce both the electrical power demand for average street use and also reduce fan noise. By starting fan at lower temperature with lower speed, it smooths out system temperature peaks and reduces overall load. If run live after turn-off, this also saves battery capacity for restart. Component design descriptions for proven as-built system with usage details. Design for stock L16, L18, or L20B engines, Likely a great upgrade for other engine swaps such as SR20, KA24, etc. The devil is in the design details. The circuit set up for a single fan but can be easily adapted for dual fan system. Fans suggested are oriented toward low power consumption, low profile, and lower noise and well suited for as-designed design radiator. Higher CFM versions are applicable with double the amperage requirement, taller profiles (less engine room) and nearly double the flow rates. As noted, fan choice dependent on engine build, driving style, local climate, and alternator capacity (harness suitability). Engine cooling system design requires consideration of coolant operating temperature (thermostat), radiator efficiency with available heat disposal capacity per given installation, fan switch temperature ratings coincident with placement within radiator, engine size, fan flow capacity, etc.© Axsys Technology Ltd.

-

- datsun 510 wiring

- electric fan

-

(and 3 more)

Tagged with: